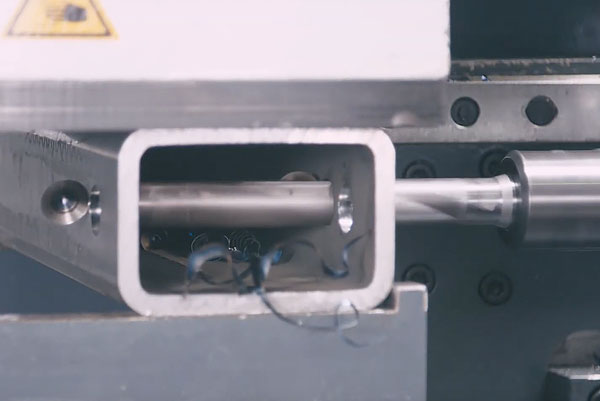

Beam Line Machine

�.. Although this machine is marketed for the Structural fabricators, I knew immediately it would work well for drilling truck frames. The accuracy & repeatability have ensured the assembly without error. The Avenger drills a set of channels for one truck in less than one 2 hours; when we did this manually, it would take 16 hours. This machine has increased our productivity & profitability hands down!..�

Even if you are programming the CNC Beam Drill Line manually, it is easy to program. Peddimat machine programming software can be used and most operators will learn how to program most of the parts in under an hour. Of course practice makes perfect. It is best to program the machine by importing parts directly from a 3-D modeling program such as ProSteel 3D, StruMis, Tekla Structures, SDS/2 or StruMis. These files are imported directly into your machine. Once you have selected the part, hit the Cycle Start button.